Top 8 Use Cases of AI And Machine Learning in Logistics and Supply Chain Processes

by

Jessica Day

March 23, 2022

In this post, guest writer Jessica Day walks us through top-8 use cases of AI and machine learning in logistics and supply chain processes.

If your business is involved in any part of any kind of supply chain, no doubt you’ve suffered over the last two years.

The sudden shock of a global pandemic may simply have left you uncertain of supply and demand forecasts. Or has it directly impacted your warehouse costs and the reliability of your shipments?

Either way, it can’t have been fun.

You need faster, better solutions to logistical hiccups and quick. These solutions can only mean one thing: more artificial intelligence (AI) and machine learning.

The bullwhip effect that pent-up demand had on global supply chains in 2021 only increased the need for automation solutions. We were already going to rely on various applications of AI and machine learning to this area of commerce and trade more and more prior to 2020.

If your logistics or supply chain teams aren’t making full use of automation yet, here are eight use cases to show you how that can change.

1. Supply chain planning and decision-making

The masses of data and statistics that certain AI tools can compile about how your company’s logistics are functioning dwarf the possibilities without them.

And more important than the data itself is the analytics that AI produces from it. Analytics can provide you with a big-picture perspective on the whole of your supply chain.

You’ll spot patterns - chronic problems to fix and areas of success to exploit further - you didn’t previously know existed. Manually produced reports just don’t provide you with the data and analytics you need by comparison.

In addition, based on AI analysis and factors you have previously determined, machine learning can make critical decisions for you. All based on the provided data to the ML model from the data annotation process.

It can help you choose suppliers more effectively. It can forecast the relative impact of various factors on your supply chain and calculate which contingency measures would suit you best. In today’s volatile climate, it can even allow you to price products dynamically, according to sudden changes in supply and demand.

The introduction of AI and machine learning into supply chain management is the most modern enterprise digital strategy out there. The relevant advanced computing tools allow you to learn more quickly from past problems, rectify current ones, and predict future threats and opportunities for your business.

2. More efficient stock management

With automation tools, you can immediately begin to cut down on wasted space in your warehouse.

Storage volumes can be increased as you reduce inefficient storage. The improved planning that AI facilitates will also prevent overbuying by introducing less wasteful practices such as product bundling.

The ability of machine learning software to predict demand and changes in this, based on the flow of goods, will also significantly improve stock management. It’s proven that the use of AI in demand forecasting reduces out-of-stock sale cancellations by 65% and warehouse costs by at least 10%.

3. Easier, faster, and cheaper shipping

Using AI when shipping goods along your supply chain can revolutionize the process, both in terms of quality and speed.

Route optimization is the most common benefit of applying AI to courier services. Delivery management software can plan routes taking into account variables beyond the reach of any human team.

For your clients and other stakeholders, intelligent software makes tracking different moving parts along the supply chain much easier as well.

You can take things a step further still. Machine learning can be programmed to detect damage to objects being delivered where drivers wouldn’t be able to, ensuring the quality of your shipments.

And the last few years have seen the proliferation of autonomous delivery vehicles like drones. These will only become even more commonplace as a cost-cutting - and often time-saving - measure, which can help your bottom line.

4. Communication

AI and machine learning can facilitate better communication at work across different departments of your logistics operation. They will also aid communication along the supply chain of which you are part, particularly when it stretches across multiple countries and continents.

Self-teaching, highly developed software tools are essential for translating critical shipment and product data between different languages. This is a widespread but under-resourced need across the global logistics industry.

Machine learning is required for the process of foreign language data cleansing too. This process is vital for stock to be sorted in the local language of a warehouse and stored properly to be easily accessible.

5. Customer service and marketing

It’s easy to forget the importance of customer service to a company’s logistics and supply chain processes. However, without good customer service, you won’t have many customers left whose demand maintains these processes.

As the best personalization websites illustrate, machine learning provides more accurate insights than a manual overview ever could into your customer’s needs.

There’s software to identify the frequency and severity of common customer pain points, and their causes can be rooted out more quickly. Customer queries can be anticipated by AI tools providing them automatic information updates.

One of the best uses of AI for customer service is in the automation of the service itself. We can automate customer service with chatbots displaying human-like empathy for customer needs while giving them the answers they’re looking for quickly and accurately.

Chatbots reduce the costs of employing human customer service advisors and also lead to faster response times for customer queries.

Self-service in logistics can be ensured with last-mile delivery tracking and customer notifications. By giving the customer a live tracking link with dynamic ETA, you eliminate the need to call and check on the status of delivery.

You can use machine learning in the marketing department as well, to automate repetitive tasks like sending out marketing emails with personalized recommendations online for individual customers.

6. Labor-saving automation

It’s not only marketers who can save on repetitive tasks through AI and machine learning. All sorts of logistics tasks, from scheduling shipments to warehouse auditing and email processing, can now be done automatically by machines.

The more you automate, the more you save on time and the unnecessary deployment of staff for routine tasks. You also increase the productivity of your supply chain and logistics processes. For example, automated Pick-to-Light systems improve pick rate productivity in fulfillment warehouses by 30-50%.

Optimized, paperless deliveries is another example of how your logistics team can save labor resources.

Learn how Veritiv Canada saves one hour of driver time daily with Track-POD

What’s more, the quality of work in warehouses and along your supply chain increases with automation. Human errors are avoided, and the accuracy of the work increases.

And machines are able to work 24 hours a day, seven days a week, without the risks of injury that human employees face when carrying out heavy-duty warehouse tasks. Intelligent robots carrying out formerly manual tasks with precision spare your workforce these dangers and save you from higher insurance costs.

7. Managing your workforce

AI and machine learning provide you with far superior tools for managing your employees to non-automated methods.

With machine learning, your workforce scheduling becomes more effective and a less arduous, time-consuming task for managers. The more advanced planning the automation of this process affords also facilitates a better division and specialization between and within different departments.

Thanks to AI, the planning and management of your workforce can take place in real-time as well. The constant collection and compilation of data from warehouses, shipping vehicles, and other parts of the logistical operation means managers can respond immediately to changes in relation to specific employee metrics.

This way of managing by incorporating AI tends to increase employee productivity. Additionally, more data awareness across the company increases the likelihood of effective team collaboration. Managers can compare how processes and procedures are impacting different employees and teams using the data AI provides.

8. Integration of systems

In fact, AI is the only mechanism by which metrics for different parts of the supply chain and logistics teams within a company can synchronize. Without the real-time integration of results and integrated analysis of those results, you can’t really have the full picture of how your company is performing.

Nor can you spot trends in the global supply chain that may be affecting your company’s performance. Different links of any supply chain are interrelated. Your system of analysis should reflect that interrelation, and so should your system of work.

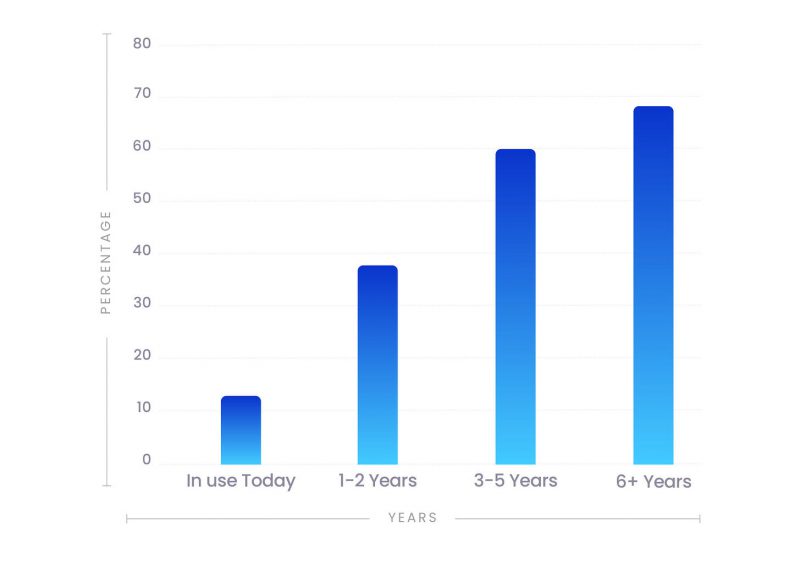

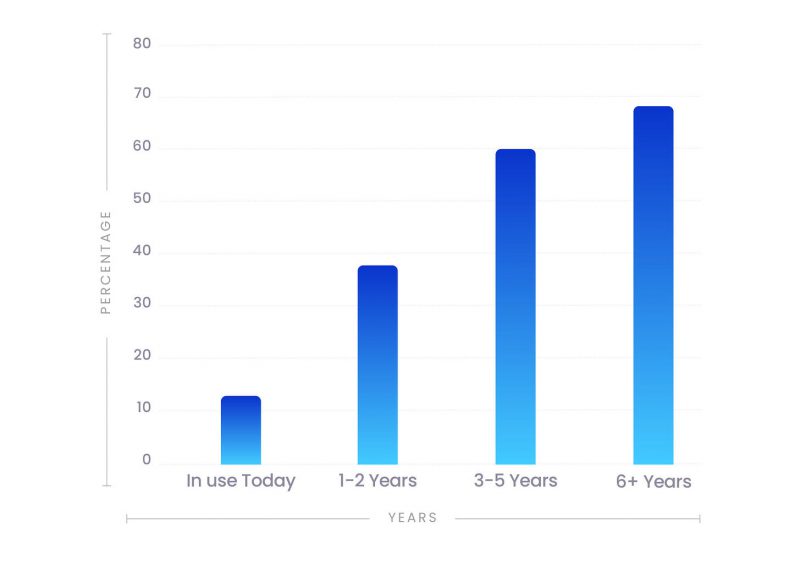

In this way, effective supply chain execution is only possible today through the extensive use of AI and machine learning. More and more logistics companies are coming to realize this truth, and most will be fully on board with AI within the next five years.

AI can end our logistical nightmares

In the current climate, no part of the world economy is in more desperate need of data-aware strategizing and decision-making than logistics and supply chains.

On an individual level, your business can play a role in satisfying this need. The more businesses adopt an AI/machine learning-based approach to logistics and supply chain management; the better global supply chains will function.

Be one of the businesses that lead the world out of its supply chain problems. Look at which of your logistics processes need automating before you’re left behind.

About The Author

Jessica Day

Jessica Day is the Senior Director for Marketing Strategy at Dialpad, a modern business cloud PBX platform that turns conversations into opportunities.