- Last Mile Delivery

- Best Practices

Best Solutions to Minimize Expenses in Logistics

by

Mike Foster

May 08, 2024

Logistics plays a crucial role in optimizing a company's operations by efficiently managing the movement and storage of goods. The pivotal question for today's businesses is: how can logistics costs be effectively reduced?

The following sections of this article will explore strategic approaches and innovative solutions designed to reduce logistics costs. It is tailored specifically for C-level executives and mid-level managers seeking actionable insights.

During tough times, smart businesses use technology to enhance their logistics efficiency. These technologies include AI, IoT, Blockchain, and Automation tools.

Business owners know optimizing logistics is vital to minimize overall business costs. So, let’s talk about the ways you can reduce the overall logistics cost of your business.

—

Jump to the most relevant part:

—

Technology for expense reduction in logistics: 4 case studies

Technology is changing the game for logistics. If you want to reduce the expense of your business, you need to start using technology. We will discuss how you should do it but ahead. For now, let's discuss the latest technologies being used.

Internet of Things (IoT)

IoT is revolutionizing logistics by offering real-time monitoring and efficiency enhancements. Equipped with sensors, IoT devices continuously track critical conditions such as temperature and humidity. It ensures that goods are transported under optimal circumstances.

Moreover, IoT technology aids vehicle route optimization, suggesting the most efficient paths to reduce fuel consumption and lower carbon emissions.

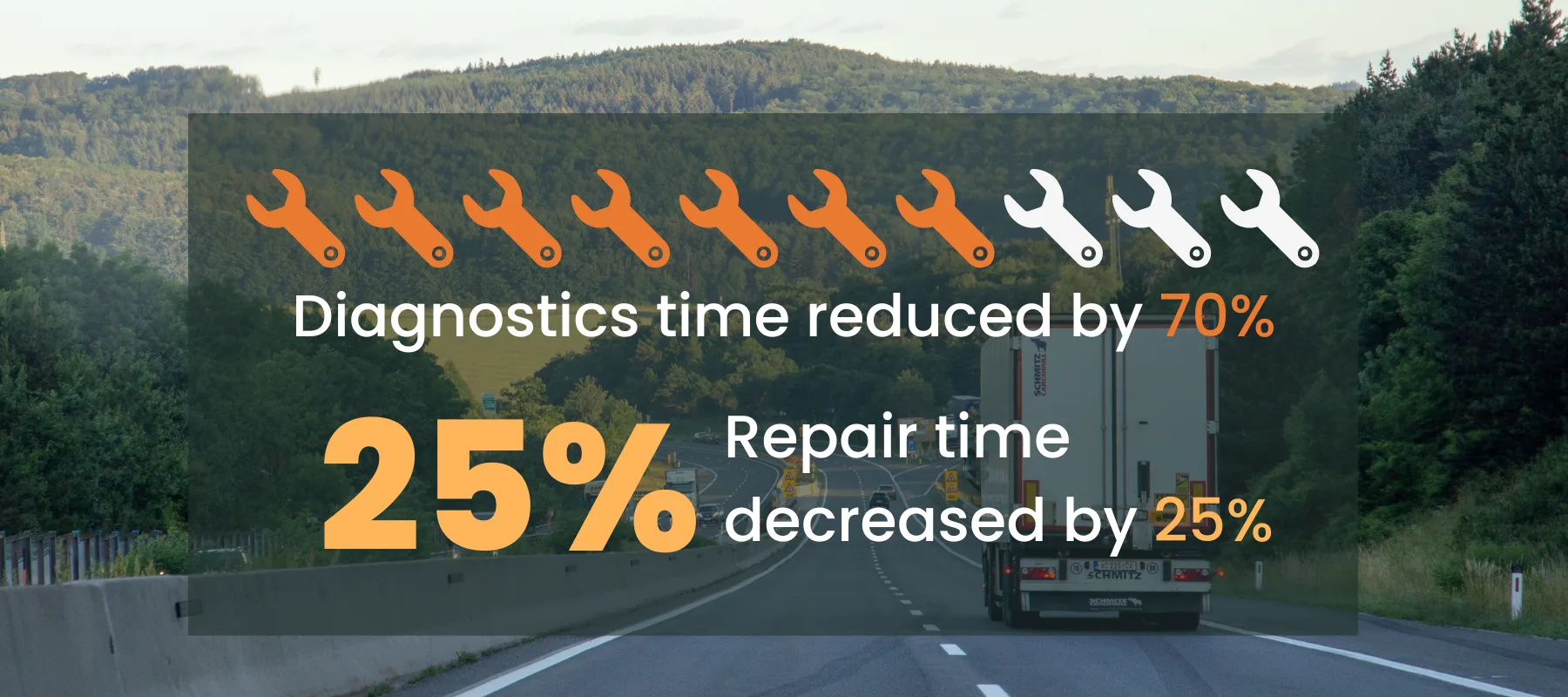

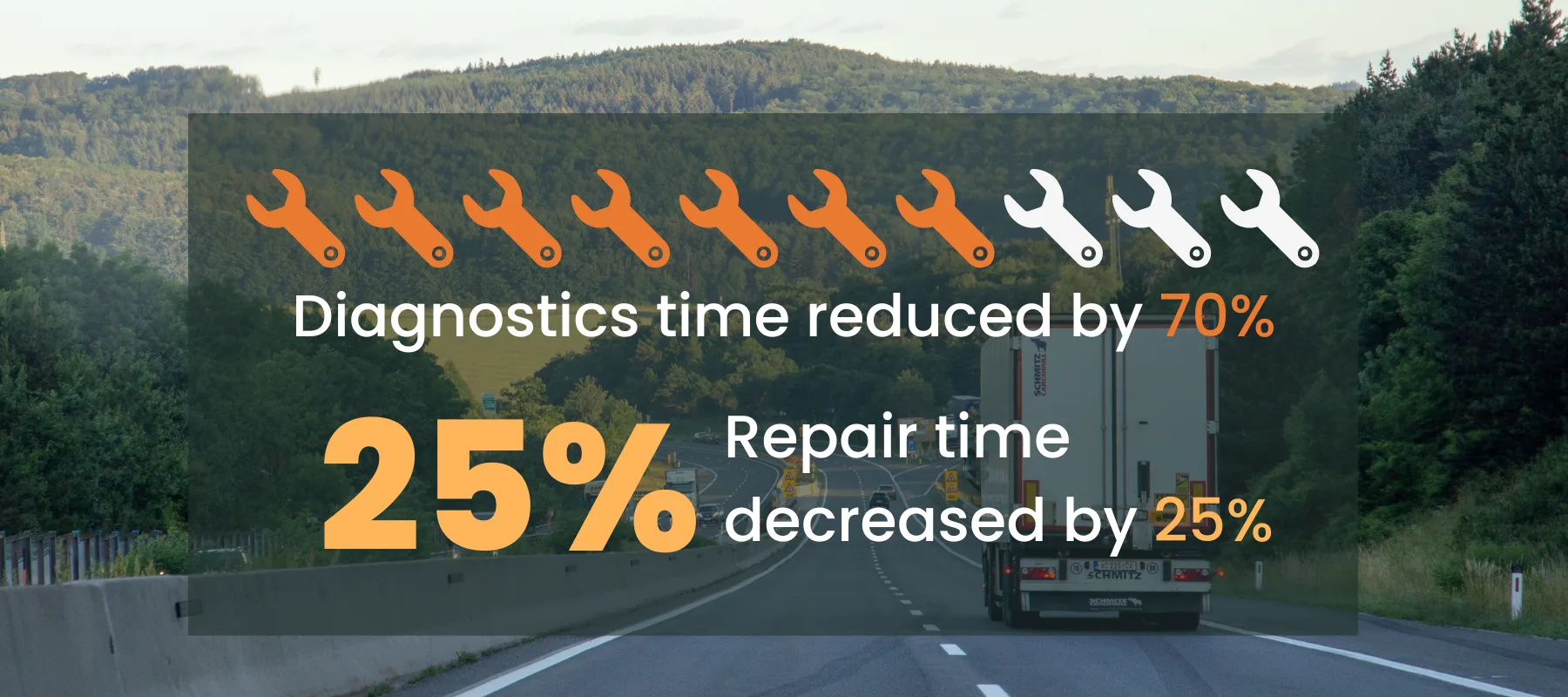

Case Study 1: Volvo

One example of companies using IoT devices is Volvo. They were having trouble diagnosing issues with their vehicles. However, after using these devices, their diagnostics time was reduced by 70%, and the repair time decreased by 25%. The IoT devices keep a close eye on the equipment and also tell the company when they should opt for maintenance.

Artificial intelligence and Machine learning

AI and ML serve as advanced tools that significantly optimize logistics operations. These technologies enhance inventory management by accurately predicting stock levels and optimizing warehouse space.

Additionally, AI and ML refine delivery schedules by forecasting demand and identifying optimal delivery routes. Furthermore, they improve customer service through intelligent chatbots that provide timely and effective problem resolution.

Case Study 2: Consumer Packaged Goods (CPG) Company

A large CPG company in Asia utilized autonomous planning to improve its supply chain management during COVID-19. They implemented advanced analytics and machine learning algorithms.

This change resulted in a 10 to 12% increase in forecast accuracy at the SKU level. On top of that, a 6 to 8% reduction was also observed in inventory for finished goods.

Blockchain technology

Blockchain technology enhances supply chain transparency and accountability by maintaining a secure, immutable ledger of all transactions. This permanent record provides clear visibility of a product's journey, ensuring that each step from origin to end-user is verifiable and traceable.

Blockchain's capabilities are particularly valuable in managing complex supply chains, promoting reliability, and fostering stakeholder trust.

Case Study 3: Walmart and IBM food trust

Walmart has partnered with IBM’s Food Trust Solution to implement blockchain technology to track the journey of lettuce from its suppliers to store shelves. This initiative was particularly significant after the E. coli outbreaks.

By creating a transparent and immutable record of transactions, Walmart has enhanced food safety significantly and reduced costs associated with food spoilage and recalls.

Automation tools

Robotic Process Automation (RPA) and other automation tools have changed how logistics works. Imagine robots zooming around warehouses, helping out with tasks. And then there are these vehicles that can move goods around all by themselves! With less need for people to step in, things get done faster and with fewer mistakes.

Plus, this neat thing called digital twins lets you test out logistics plans without actually doing them in real life. It's like having a sneak peek into the future to make everything run even smoother!

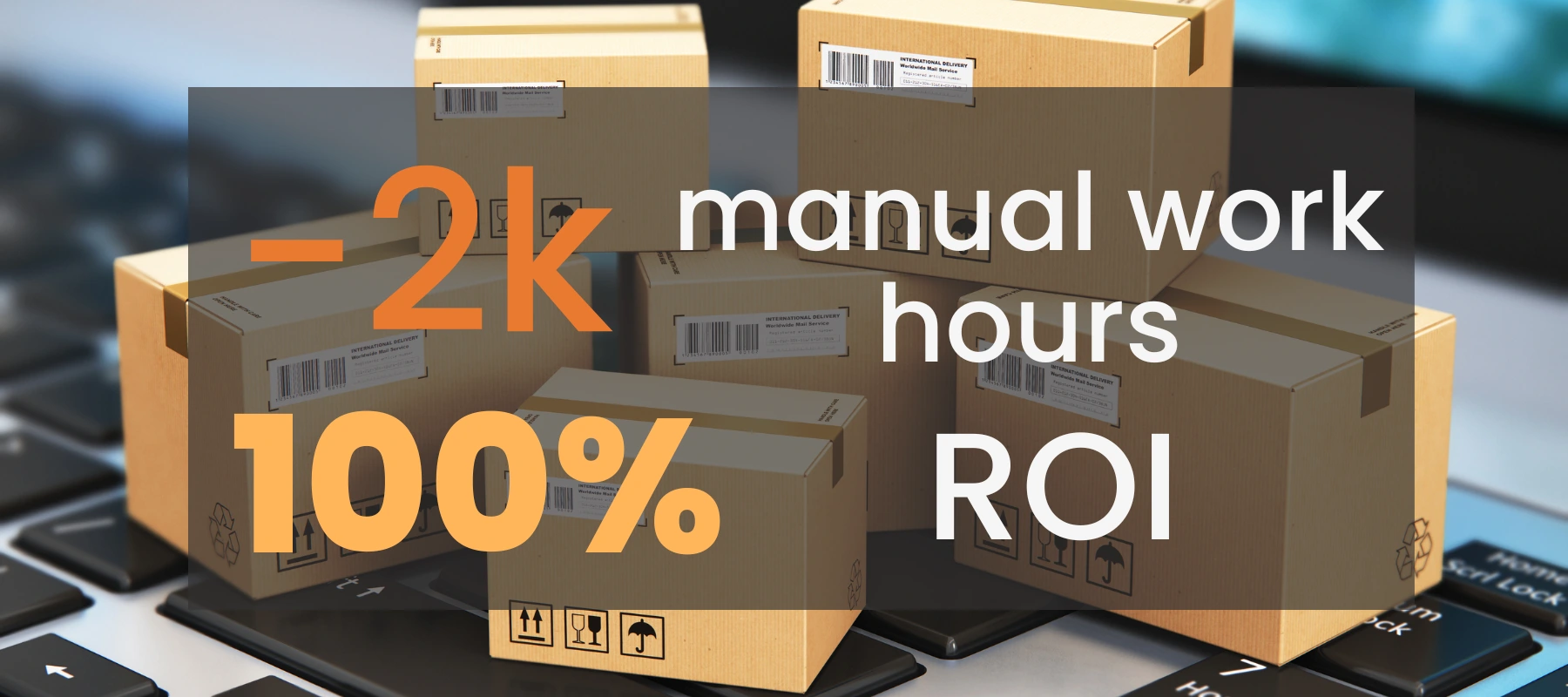

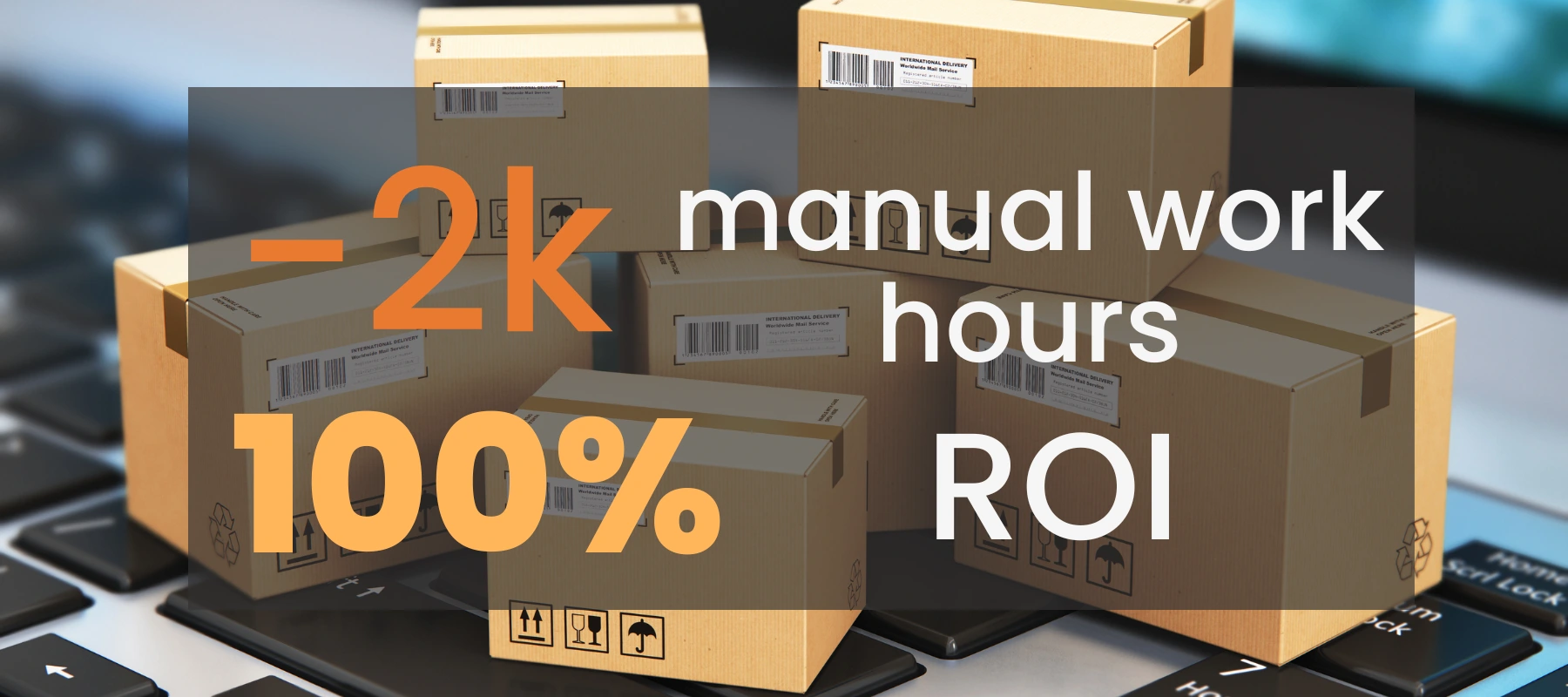

Case Study 4: Primanti Brothers

Primanti Brothers needed help to reduce their cost. So, they decided to use IBM Robotic Process Automation.

To their luck, this eliminated 2,000 manual work hours, achieving a 100% return on investment (ROI) in just three months. By implementing it, Primanti Brothers significantly reduced the time spent on tasks from 45 minutes per manager to just three minutes total for the bot to complete the job.

Ways to reduce costs in logistics

It’s important to reduce logistics costs to make your business profitable. Here are some strategies that extend beyond just technological improvements:

Process optimization

Optimizing logistics processes involves streamlining operations to eliminate inefficiencies and reduce waste. This can include:

- Analyzing current processes to find bottlenecks and redundant areas.

- Introducing just-in-time delivery systems to reduce inventory costs by receiving goods only when necessary.

- Improving route planning to minimize travel distances and fuel consumption.

Employee training

Well-trained employees are essential for efficient logistics operations. Training can lead to:

- Improved handling techniques, reducing damage to goods and equipment wear.

- Better use of technology and tools, such as advanced inventory management software or automated systems.

- Enhanced safety practices that minimize accidents and associated costs.

Adopting lean logistics principles

The next thing you can do is adopt Lean logistics. It is all about cutting out waste in the logistics process. Some key ideas in lean logistics include:

- Remove steps that don't benefit the customer

- Continuously seek cost reduction, quality improvement, and efficiency enhancement

- Cut down on overproduction and storage costs by matching production to actual demand

Strategic supplier partnerships

Building strong relationships with suppliers can lead to cost reductions through:

- Bulk purchasing agreements that secure lower prices.

- Collaborative planning and forecasting to improve inventory accuracy and reduce excess.

- Shared logistics services with other businesses to split costs.

Effective inventory management

Proper inventory management ensures that capital is not tied up unnecessarily and storage costs are minimized. Techniques include:

- Demand forecasting to better align inventory levels with consumer needs.

- Stock reviews and regular audits to reduce overstocking and obsolescence.

- Cross-docking to reduce the need for storage. Directly transfer products from incoming to outgoing trucks.

Sustainable practices

Adopting environmentally friendly logistics practices can reduce costs and appeal to increasingly eco-conscious consumers. Options include:

- Alternative fuels or electric vehicles should be used to reduce fuel costs and potential future carbon taxes.

- Optimizing packaging to reduce material use and waste.

- Increasing load efficiency will make better use of transportation space and reduce trips.

Automated order routing for better operational efficiency

In logistics, saving money comes from using better technology, improving how things are done, and planning smartly.

Things like routing algorithms, automated warehouses, and keeping track of products in real-time can make a big difference in how much it costs to run things while also improving the service.

Skuba Group's efficiency boost: Track-POD's automated routing success

Skuba Group utilized Track-POD's automated routing to optimize their delivery schedules and routes. This technology allowed for precise timing and route efficiency, doubling the company’s operational efficiency. The implementation significantly reduced idle times and unnecessary travel, maximizing fuel efficiency and improving overall productivity.

Siuntų Pilotai's efficiency leap: Track-POD integration success

Siuntų Pilotai integrated Track-POD’s customer portal, which provided tools for better order and delivery management. This solution reduced operational expenses by 75% through improved logistics coordination, which streamlined the interaction between dispatchers and drivers and significantly expanded their handling capacity without physical space expansion.

Logistics expense examples

Logistics expenses encompass a variety of costs critical to the successful movement and storage of goods.

Transportation costs

Moving goods around costs a lot for businesses. If they don't make it efficient, it can really hurt their wallets. This includes paying for gas, fixing trucks, and paying the folks who drive them, plus fees for moving products.

To spend less, companies can use special computer programs to plan the best routes for delivery, combine shipments to fill up trucks, and try to get better deals from the folks who move their goods. By being smart about how they move things around, they can save a lot of money.

Warehousing costs

Warehousing is another critical area where costs can quickly add up, from renting spaces to paying utilities and staff. Optimizing the use of space with vertical storage and organizing inventory efficiently can dramatically reduce costs. Some businesses are also turning to automation to enhance efficiency and reduce labor costs, or even outsourcing to third-party logistics providers for potentially cheaper and more flexible storage solutions.

Inventory costs

Storing things costs businesses money. They can use a Just-in-Time (JIT) system to avoid having too much goods sitting around, which saves money. Checking what's in storage regularly can help get rid of extra or old products, and getting better at guessing how much goods they'll need can stop them from buying too much. It's all about saving money by keeping just what they need.

Packaging costs

The cost of packaging materials and the labor to package goods can be considerable. Adopting standard sizes and materials for packaging helps streamline operations and reduce costs. Additionally, using sustainable materials can be cost-effective, potentially aided by tax incentives. Buying packaging materials in bulk can also lead to significant savings through volume discounts.

Regulatory compliance costs

Following shipping rules, both locally and internationally, is super important and can cost a lot if you mess up. Keeping up with any changes in the rules and making sure everything you do follows them can help you avoid big fines and delays. Making sure all your paperwork is in order and using systems that do it automatically can make things run more smoothly, especially when you're dealing with customs.

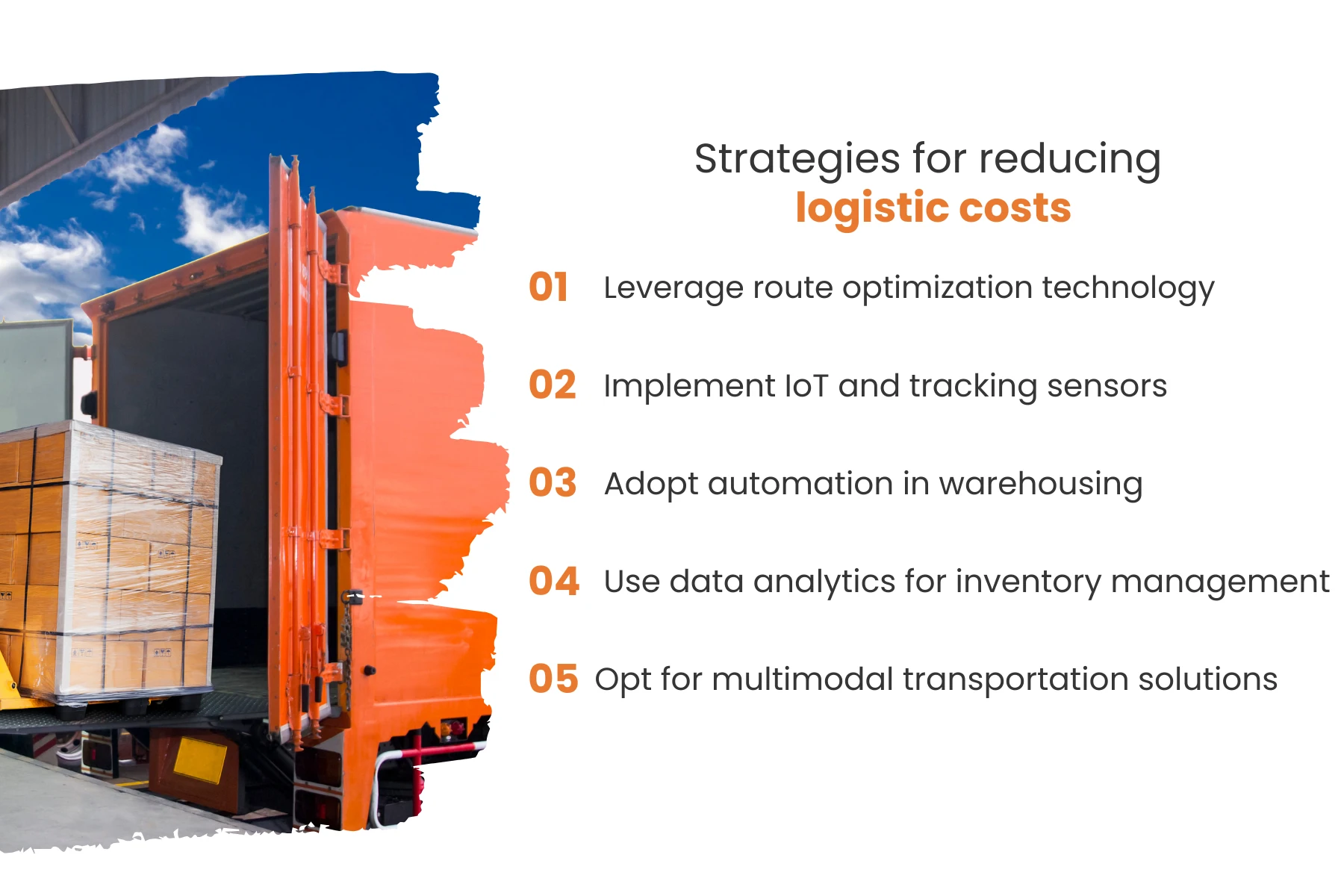

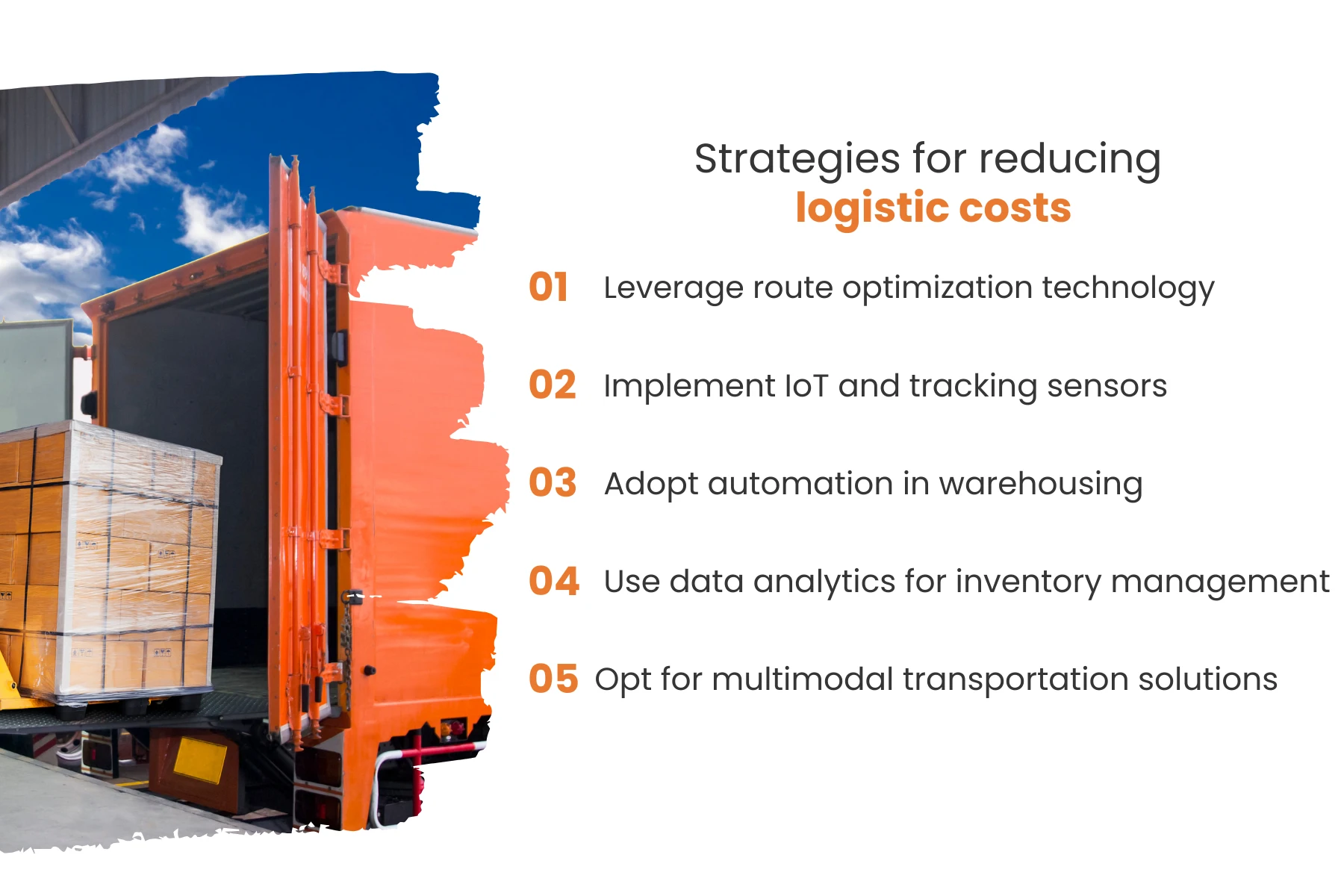

Strategies for reducing logistic costs

Leverage technology for better route optimization

To economize on logistics expenses, optimizing delivery routes stands out as a top strategy. Sophisticated software employs advanced algorithms to calculate the most efficient paths for delivery trucks, resulting in reduced fuel consumption and heightened delivery frequency each day.

Additionally, GPS tracking enables trucks to dynamically adjust their routes in response to real-time factors like traffic congestion, further enhancing time and cost savings.

Implement IoT and tracking sensors

Imagine putting special devices on containers and vehicles. These devices help you keep an eye on your shipped products in real-time. This means your deliveries get there quicker and with less chance of things getting lost or broken. Plus, they can help make sure things like food stay fresh by checking the temperature and humidity all along the way.

Adopt automation in warehousing

If you start using automation in your warehouse, you’ll see that your costs have decreased drastically. Manual labor causes a lot of trouble because of human errors which adds up on the business cost.

However, robots can handle tasks more efficiently than humans. This reduces the risk of and speeds up the process. A bit of bad news for laborers, but businesses have to think about their costs as well.

Use data analytics for inventory management

In one of our previous blogs, we talked about how Data can improve overall logistics. To summarize that, Data analytics can transform inventory management by predicting demand more accurately.

Also, by analyzing sales data, seasonal trends, and even social media trends, businesses can have a more accurate forecast of what needs to be stocked and when. This optimized inventory management prevents excessive storage costs and product obsolescence.

Opt for multimodal transportation solutions

Relying on a single mode of transport can sometimes become costly. It’s important that you use a combination of transport modes.

These modes could include shipping goods via rail instead of trucks for long distances, which can reduce costs significantly. Multimodal transportation management systems can help plan and execute these strategies effectively.

How does technology benefit logistics?

Using technology in logistics has a bunch of advantages. These fancy new tools help make operations smoother and make logistics work better. Some of the benefits include:

Cost reduction

Technology in logistics offers substantial cost savings as one of its key advantages. Automating warehouse operations minimizes labor expenses, and errors stemming from manual handling are decreased.

Additionally, route optimization software ensures vehicles take the most efficient paths, thus cutting fuel costs and lessening wear on fleet vehicles. Predictive analytics further reduce cost by accurately forecasting demand, enabling companies to optimize inventory management and minimize excess.

Enhanced efficiency

The integration of technology greatly enhances efficiency within logistics operations. Real-time tracking systems facilitate continuous monitoring of goods across the supply chain, fostering transparency and enabling swift responses to potential disruptions.

Meanwhile, automated sorting systems and robotics accelerate warehouse processing, streamlining operations. AI-driven tools aid in scheduling maintenance for transportation vehicles at opportune intervals, minimizing downtime and maximizing efficiency.

Driving innovation

Innovation within logistics is propelled by technology, unlocking fresh opportunities for service and product delivery. Drone technology and autonomous delivery vehicles, for instance, are transforming last-mile delivery, potentially offering swifter and more cost-effective delivery solutions, particularly in urban settings.

Similarly, blockchain technology introduces novel approaches to secure and streamline supply chain documentation, fostering trust and facilitating smoother transactions among global trade partners.

Improved customer satisfaction

Enhanced tracking and management systems benefit logistics operators and improve customer satisfaction.

Customers today expect fast, transparent, and reliable delivery services. Technologies that provide real-time updates and estimated delivery times cater to these expectations, thereby enhancing the customer experience.

Moreover, AI and machine learning can analyze customer behavior and feedback to refine delivery processes and personalize services, aligning closely with customer preferences and expectations.

Conclusion

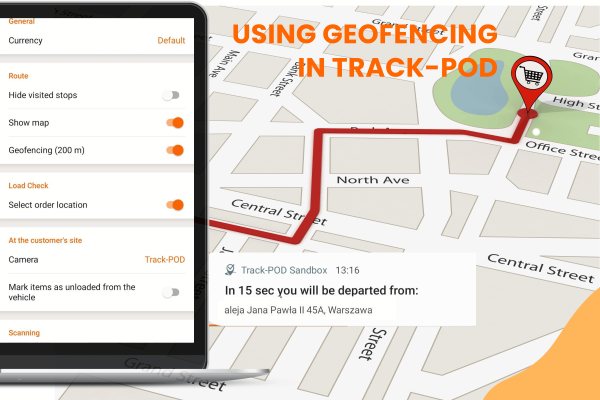

In the end, it is key that you adopt the latest cutting-edge technological solutions like automation, real-time data analytics, and AI. They help to streamline your operations. If you want software to help improve your overall logistics, check out Track-POD. It is an advanced route planning and fleet optimization software that leverages the power of AI to improve delivery precision and operational efficiency.

By integrating our software into your logistics strategies, you can not only meet the current demands of efficiency and cost reduction but also enhance your service delivery models, ultimately driving significant business growth and customer satisfaction.

About The Author

Mike Foster

A dynamic writer whose passion for technology and Software as a Service (SaaS) is the driving force behind his compelling work.