DIFOT vs OTIF: Meaning & How to Measure and Improve?

by

Yulia Miashkova

April 27, 2022

How do you know your delivery operation is efficient and scalable?

You look at analytics and performance insights. But what kind of analytics is the North Star metric of any logistics enterprise?

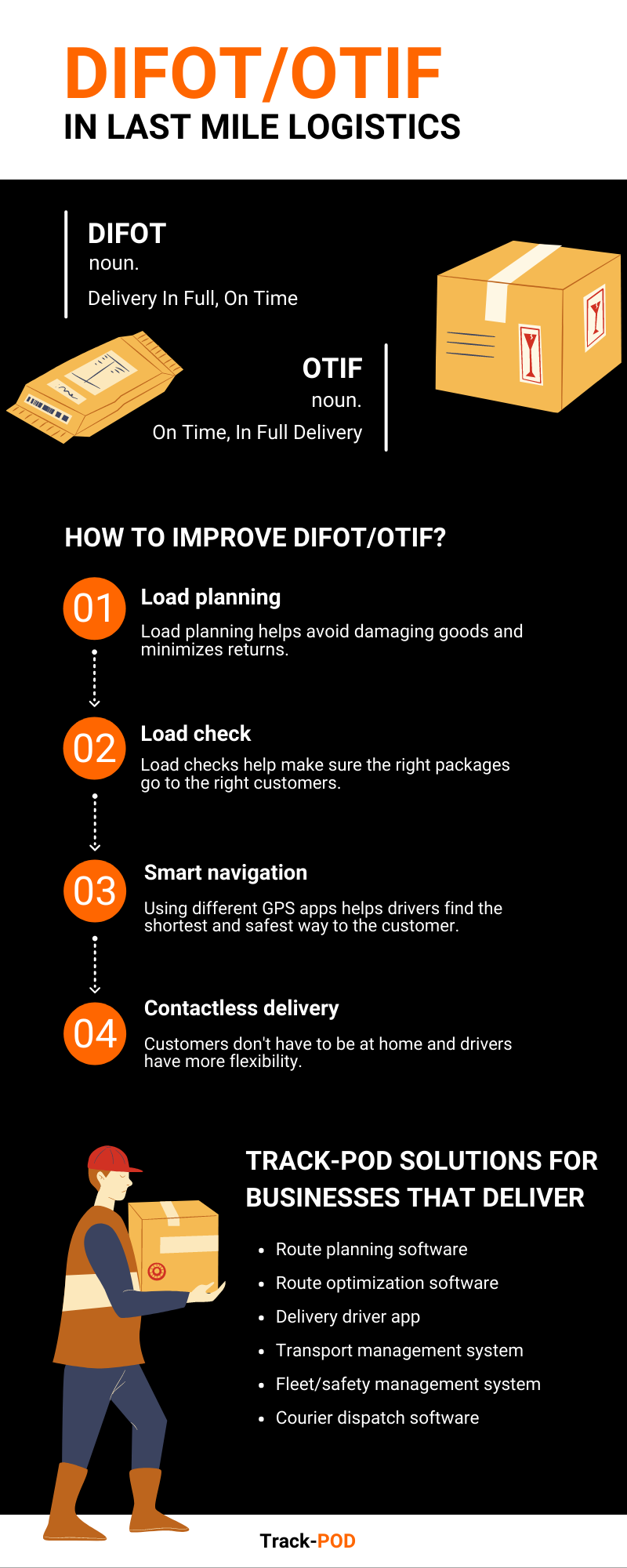

Delivery In Full, On Time (DIFOT) aka On Time and In Full (OTIF) Delivery.

In this blog post, we take a close look at DIFOT vs OTIF metrics: how to calculate, monitor, and improve yours.

OTIF, DIFOT meaning and definition

What does it mean to deliver in full and on time?

Delivery in full means that all items in the order have been delivered and accepted by the customer.

In this case, the quantity ordered matches the quantity delivered.

Let's say you have 5 boxes to deliver to a customer's address. If one of the boxes gets damaged during transportation or mixed up due to human error, the customer will reject it. Then the order can't be considered delivered in full.

Meanwhile, delivery on time means that the actual time of the driver's arrival at the customer's address corresponds to ETA.

DIFOT and OTIF are interchangeable. Logistics operations can choose either one as the main key performance indicator (KPI) that will be measured continuously to assess performance.

DIFOT, OTIF calculation

How do you calculate delivery in full and on time? Let's find out.

Delivery in full

Delivery in full is a straightforward metric to calculate. Let's take Track-POD's workflow as an example and see how this works in practice.

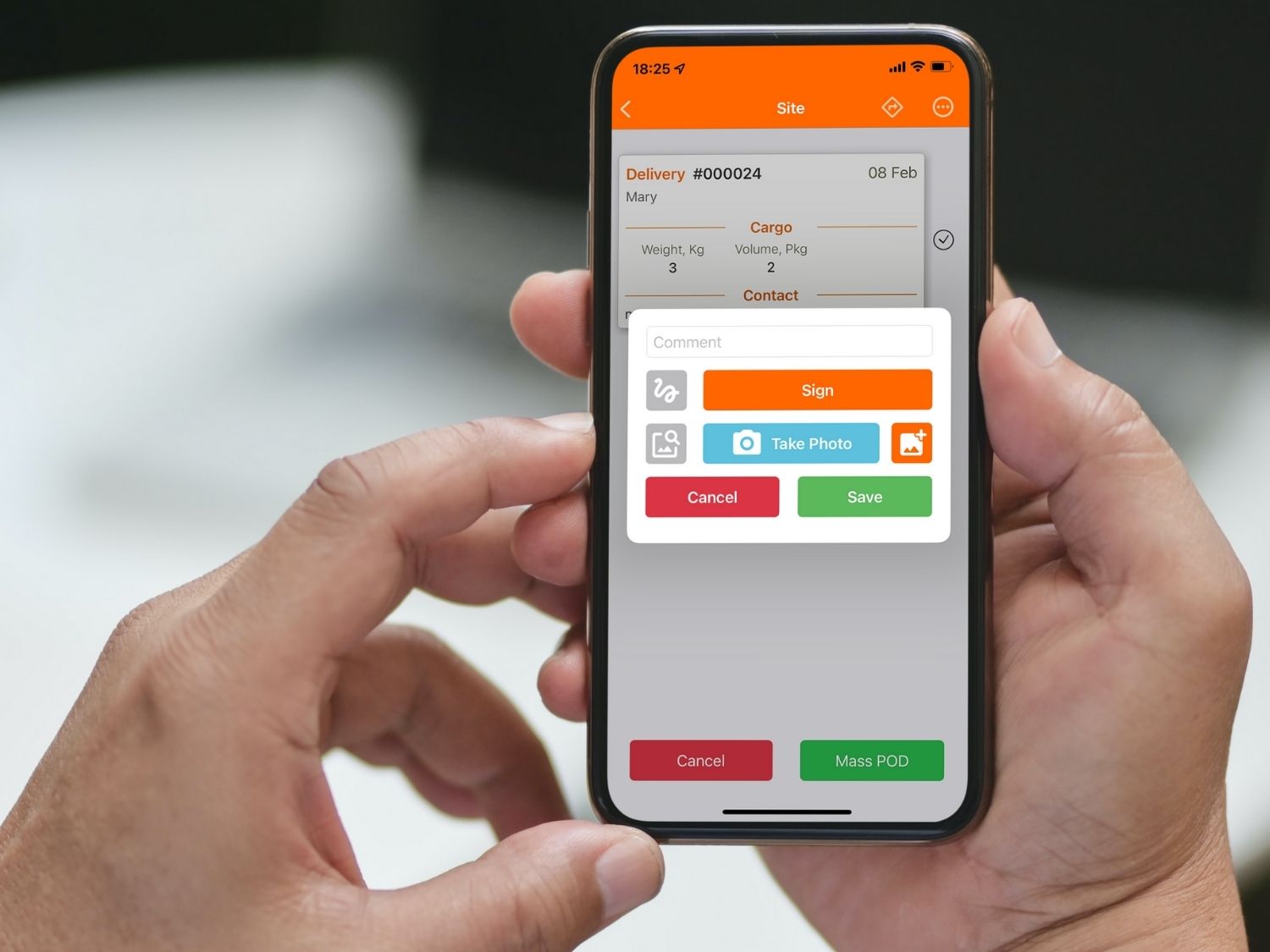

In Track-POD, there are 3 order statuses that the driver can specify after they've completed the delivery service.

- Delivered - all items in the order have been delivered by the driver.

- Not delivered - the delivery was unsuccessful (due to order issues or site issues).

- Partially delivered - some items in the order have been delivered while some have been rejected.

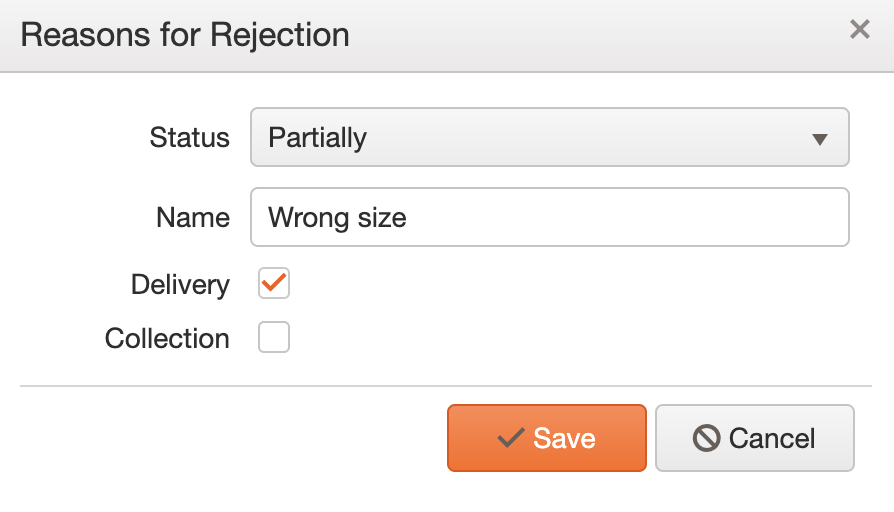

Drivers who use the Track-POD mobile app for Proof of Delivery can also indicate reasons for rejection, e.g. wrong address, canceled order, customer not at home, etc.

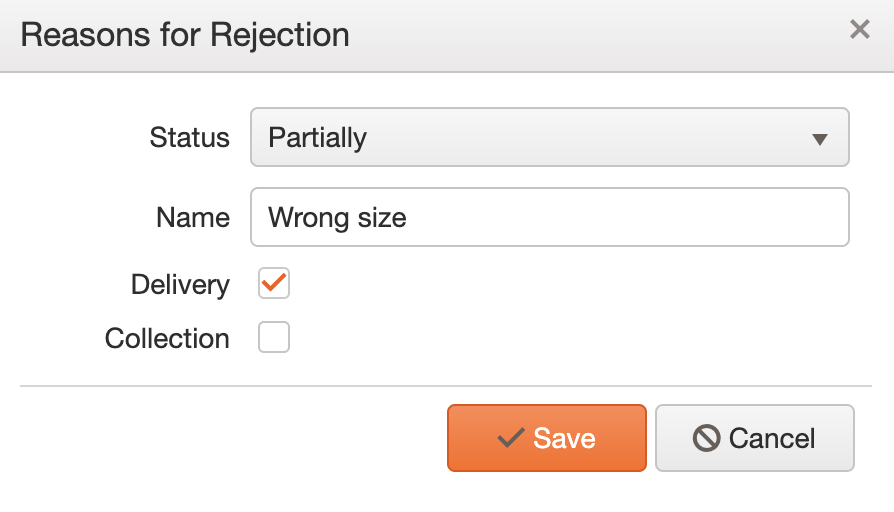

The list of reasons for rejection in Track-POD is fully customizable and you can add as many reasons as makes sense for your businesses and most common cases.

Delivery on time

Delivery on time is a little more subjective as it's determined by the logistics manager.

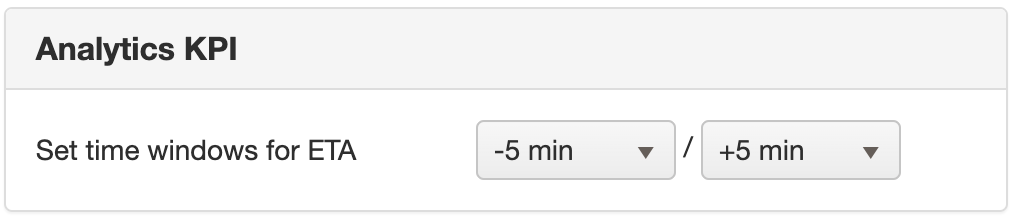

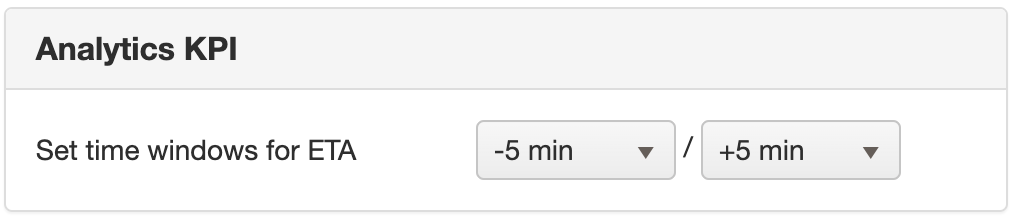

The only question is: how big of a time difference do you allow between your drivers' ETA (estimated time of arrival) and the actual time of arrival?

With Track-POD, you can set time windows for ETA. This means that you can allow a 5-90 min gap between your drivers' planned and actual time of arrival for the delivery to be considered on time.

This is something every logistics manager needs to decide for their operation.

If your type of delivery services are not time-sensitive then you can set the window up to 90 min and the delivery will still be considered on time.

This can be the case with contactless delivery when the driver doesn't need the customer's presence and e-signature and can leave the package at the specified address.

How to monitor DIFOT, OTIF?

To keep track of delivery in full and on time, especially when you have a high number of orders daily, you need reliable analytics tools.

Let's look at the kind of analytics you get as part of Track-POD web and mobile solutions for delivery management.

Analytics is where your performance insights are stored for up to 2 years under Track-POD's Advanced+ subscription plan.

You can switch between the old and the new versions of Track-POD analytics to see which one you prefer.

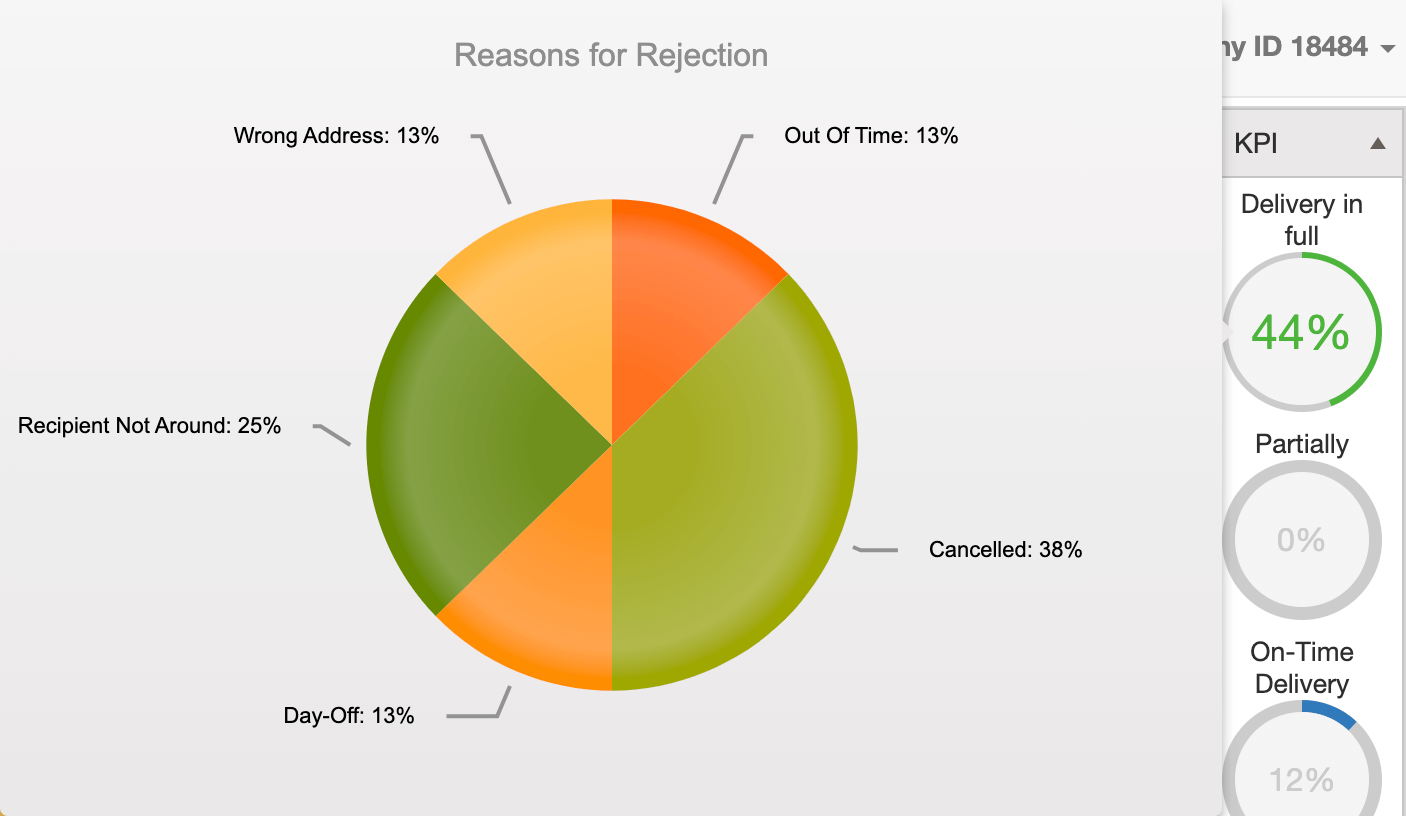

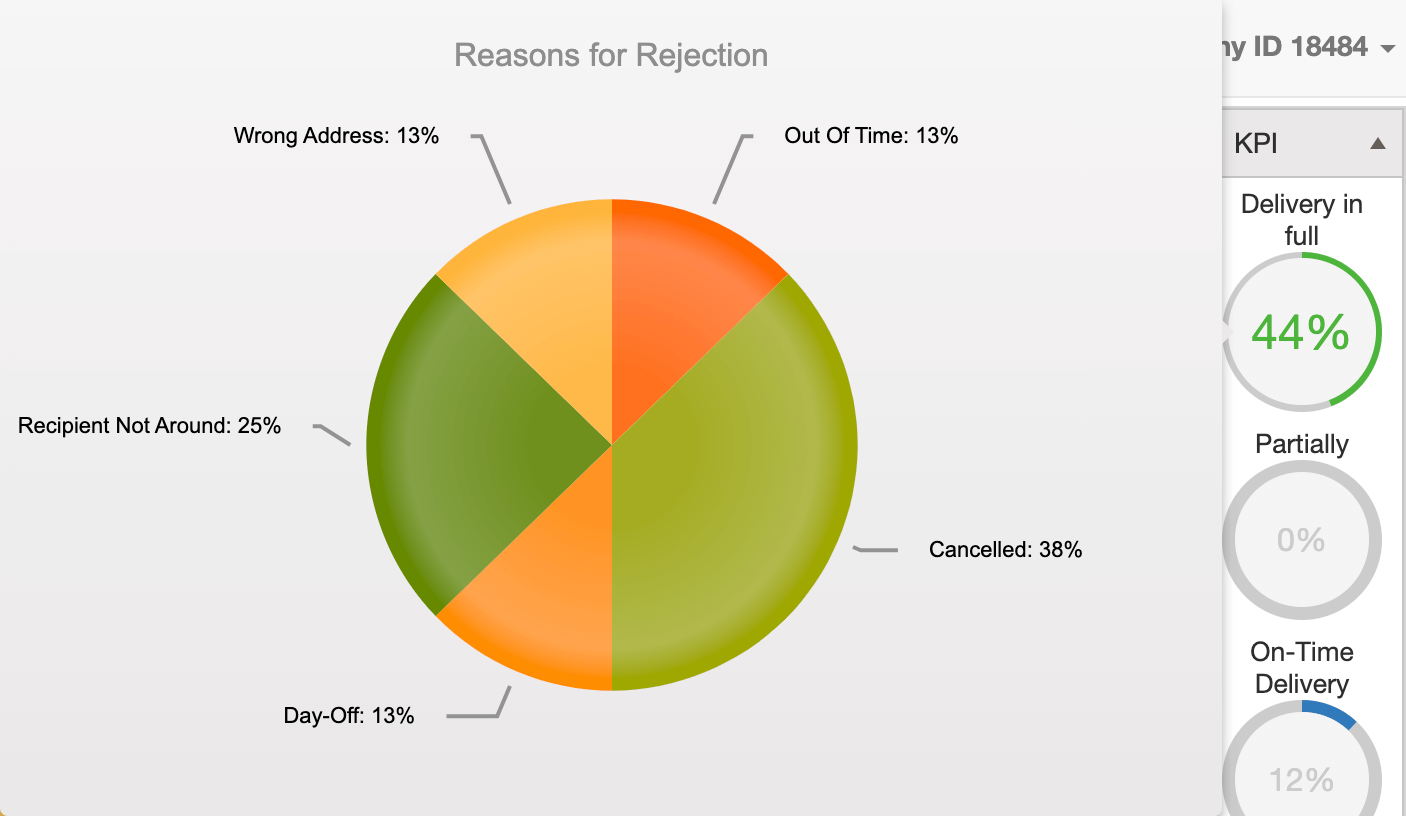

In addition to a full overview of order and route details, as well as electronic Proof of Delivery (ePOD) details you get to see your KIPs.

- Delivery in full.

- Partially.

- On-time delivery.

- Average service duration.

- Feedback.

If you hover over Delivery in full, in addition to the percentage calculated by Track-POD you get a breakdown graph with reasons for rejection of items within the orders.

Pro tip: users of Track-POD Route Manager app for Android can access order analytics on the go and track the performance of individual drivers throughout the day.

How to improve DIFOT, OTIF?

Now that we've sorted out what delivery on time and in full means and how you can monitor it, let's look at the ways to improve your North Star delivery metrics.

Load planning

Load planning is an essential part of route optimization. The point of load planning is to use your fleet resources to the max while accounting for all requirements and restrictions.

For example, you wouldn't want goods to get damaged because of how they're arranged in a vehicle, or because the vehicle doesn't meet the requirements for transportation of the goods, e.g. temperature control.

Using route optimization software such as Track-POD, you can delegate load planning to AI and use your resources to the max while making sure no goods get damaged and rejected by the customer.

Load check

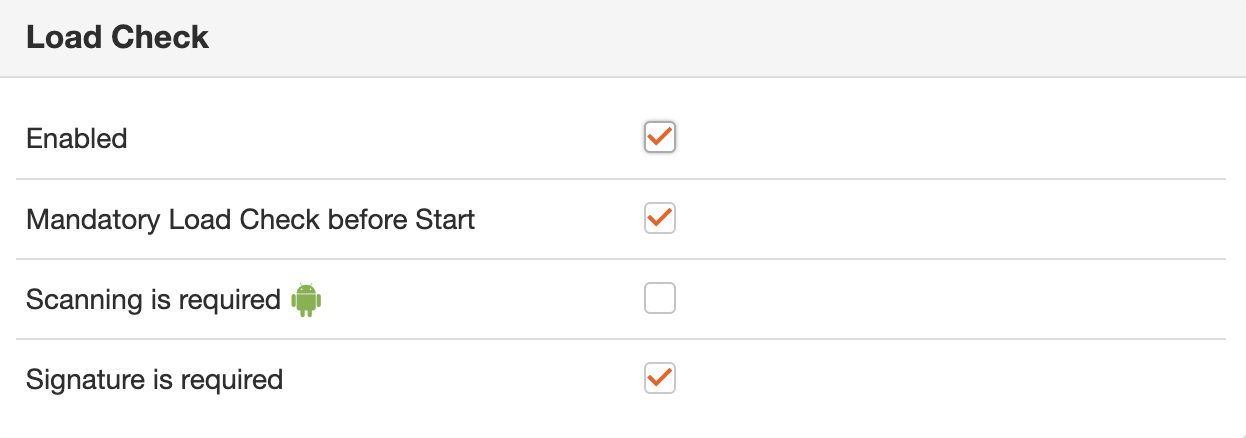

Load check is another feature that helps you cut the rate of unsuccessful and partial deliveries and up your rate of delivery in full.

Essentially, load check is scanning QR and barcodes on shipping labels to make sure the right packages are heading to the right customers.

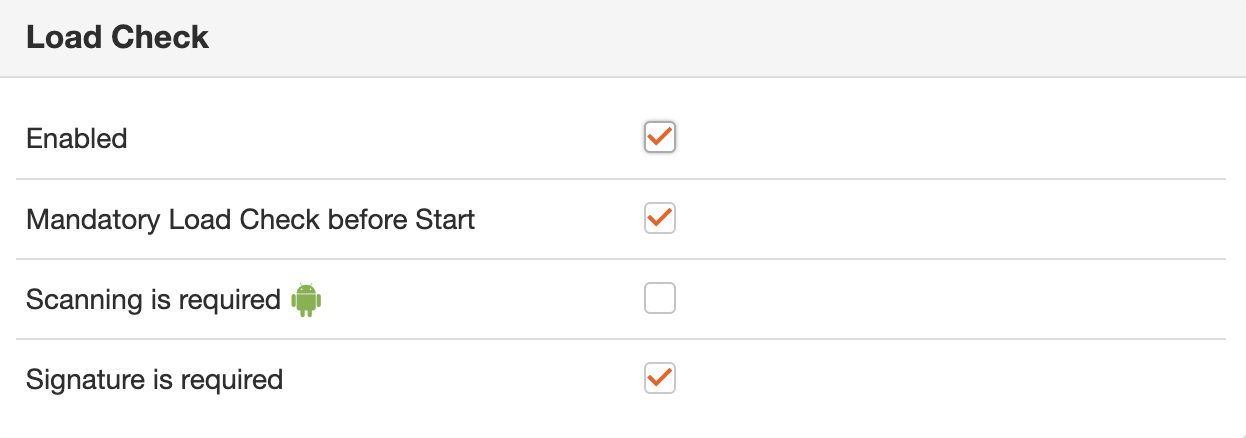

Track-POD offers a QR and barcode scanner as part of its mobile app for the driver available for iOS and Android. You can make load check mandatory before each route and even require a signature to consider a load check completed.

Navigation

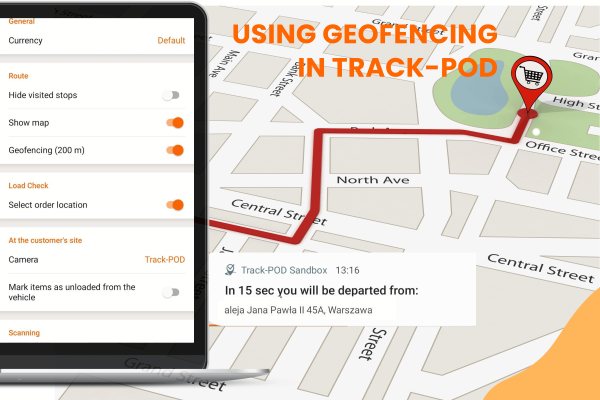

Route optimization alone is not enough to safeguard a high rate of on-time deliveries. Your drivers need to do their part and make sure they follow the shortest, safest route created by your route optimization software.

To help couriers navigate safely to customers' addresses within the route, Track-POD offers all the best GPS apps for truck drivers in one place.

Users of the Track-POD mobile driver app can switch between different navigation systems and use the one that works best in each area, making sure they arrive at the customer's address on time.

Contactless delivery

Contactless delivery is a win-win when it comes to improving your DIFOT or OTIF.

On the one hand, it gives customers the flexibility to not be at home when their order is delivered or not be in physical contact with the driver.

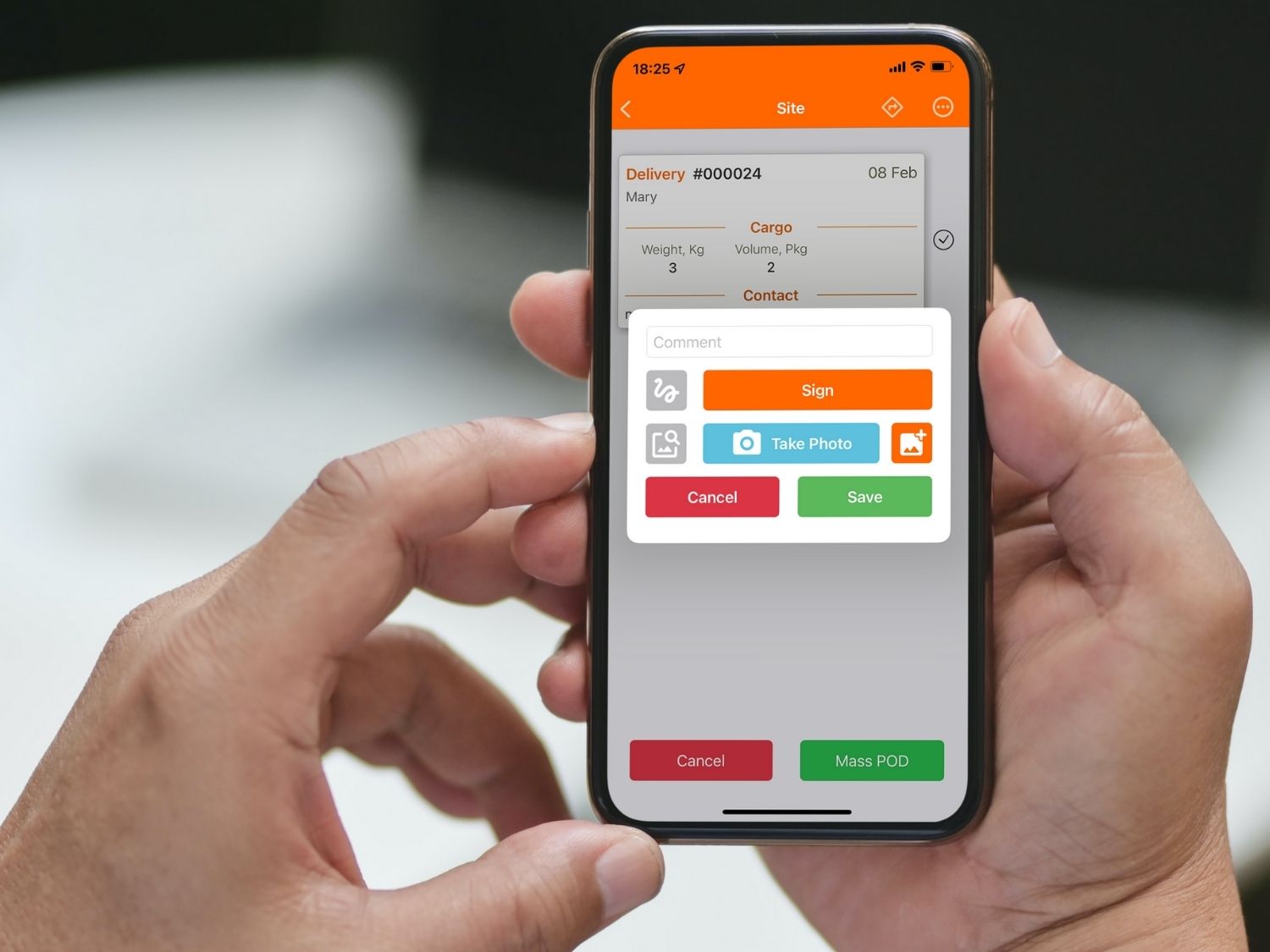

On the other hand, it gives you the option to define a wider timeframe for delivery on time because all your drivers need to do is take a photo of the delivered package. The photo will then populate a Proof of Delivery PDF that is shared with the customer right away.

Wrapping up

To deliver in full, on time is to provide a good delivery service. With the right tools and workflows in place, you can measure, monitor, and improve your DIFOT or OTIF metrics continuously.

If you're curious about Track-POD solutions for on time, in full delivery, book a demo or start your 7-day free trial today to see the software in action.

About The Author

Yulia Miashkova

Growth marketing manager with a background in public relations, SEO, social listening, and Account-Based Marketing.