10 Tips for Wholesale Inventory Management in 2024

by

Jennifer Collins

May 31, 2024

The wholesale inventory management landscape is rapidly changing due to new trends such as updated technology and AI and the need for sustainability. For wholesale businesses to retain their competitive edge in 2024, it is essential to stay informed and embrace the latest technologies to help streamline processes and optimize stock holding. More statistical insights into the wholesale market can be found here.

Sustainability and proficiency in the wholesale warehouse environment include the effective management of inventory levels to reduce warehouse overheads and to help wholesalers maintain competitive pricing structures and improve their profit margins.

10 tips for efficient wholesale inventory management

We hope the following tips will help key warehouse personnel in their quest for effective, cost-efficient inventory management.

In this chapter:

1. Analyze and build forecasts

2. Perform regular stock audits.

3. Categorize your stock

4. Implement stock-ordering strategies.

5. Collaborate with marketing and sales.

6. Optimize your inventory processes.

7. Sell stock at discounted prices.

8. Get rid of slow-moving or obsolete stock.

9. Supply chain awareness.

10. Optimize logistics processes

1. Analyze and build forecasts.

Sound analytics and forecasting strategies in the wholesale inventory management system will help managers to analyze current inventories and predict future stock requirements.

Inventory analytics helps you to identify:

- Stock shrinkages are due to theft or operational errors.

- The costs of carrying stock, including price and overheads.

- Inventory turnover ratios indicate how sales affect inventory items.

- Backorder levels or lost sales due to insufficient stock.

Analytics are also used to collect data for forecasting models to use in predicting future stock requirements and buying patterns.

Pricing strategies can be managed using analytics that determine current market prices and trends.

2. Perform regular stock audits.

Stock audits serve two essential functions:

- To identify discrepancies, or shrinkage, between physical stock in the wholesale warehouse and the inventory system quantities.

- To determine the value of your stock and how much it costs to keep it.

By doing regular stock counts, managers stay in touch with what is happening in their warehouses. They have more control over their stock and can proactively manage problems before they get out of hand.

3. Categorize your stock

Inventory is easier to manage if it is categorized within the wholesale inventory control and inventory management system. This can be done by product type or by separating products into high-, medium-, and low-value items. Alternatively, you can categorize inventory into fast-, medium-, and slow-moving items, depending on how you would like to manage your stock and the type of products you keep.

Categorization helps you when doing stock counts. For example, you can count the fast-moving items every week and the slow-moving items less frequently. If you categorize by value, the high-value items can be stored in a safer bin environment, with limited access to key personnel only. Categorization gives warehouse management the flexibility to increase prices on specific categories only.

Technology can be utilized within inventory management. Inventory management software for wholesale businesses should be able to increase stock by percentage or amount across entire categories.

4. Implement stock-ordering strategies.

As discussed, keeping too much stock in your warehouse will take up valuable space and increase costs. On the other hand, keeping low stock levels increases your risk of running out of stock and losing customers as a result.

Wholesale inventory management systems generally provide various methods for determining when to order stock and how much.

- Adding a conservative safety level to your stock item will help to avoid stock shortages.

- Add a minimum stock level to individual products so that when you reach that minimum figure, the system will advise you to reorder.

- Add a maximum order level so the system will warn you when you’re in danger of overstocking that item.

These methods require system intervention and system notifications.

Manual methods can be used, such as periodic stock counts, which enable you to determine stock levels and make decisions about reordering quantities.

Without system notifications, a multi-bin system can be used to monitor stock levels. It involves keeping stock in two separate bins. When one bin runs out, you know it’s time to order, and the second bin should contain enough stock to see you through until the replacement stock arrives for the first bin.

5. Collaborate with marketing and sales.

Marketing strategies usually involve promoting certain products, and inventory managers need to be aware of these promotions so that stock levels can be aligned with them and expected sales.

Sales personnel also have a good idea of customer preferences and needs. Regular meetings between inventory, sales, and marketing management are essential to discuss the latest trends and strategies and their impact on stock levels.

6. Optimize your inventory processes.

Improved processes mean efficiency in-stock orders, picking, and delivering to your customers or other warehouses.

Automation of warehouse equipment plays a big role in improving inventory operations.

The latest IoT technology facilitates communications between various digital tools and systems, empowering wholesale order management systems and wholesale inventory management systems to communicate with robotics, product scanning devices, barcode readers, forklifts, conveyors, and drones. When using these tools, the packing, binning, picking, and dispatching of stock is automated, speeding up processes and enabling warehouse staff to control the processes rather than do the physical work themselves. These tools also help to eliminate the human error factor.

Setting up an automated operation may require a large capital outlay, but the cost savings that come with an optimized inventory management system will exceed the cost of the outlay after a period of time.

7. Sell stock at discounted prices.

Inform marketing and sales when stock is not moving and create a plan to promote unwanted products by advertising them at discounted prices. If practical, salespeople can be incentivized to push sales on certain products.

8. Get rid of slow-moving or obsolete stock.

When trends change and stock is not moving, either stock items become redundant because something else has taken their place, it is time to get rid of products that are taking up space and draining cash flow. Some ways of doing so are present below:

- Bundling the products, making package deals. Be creative and bundle slow-moving products with fast-moving items in a similar category. An example of bundling products is adding a lunch box or water bottle to a back-to-school stationery pack guaranteed to sell. Bundled products are attractive to consumers, and it’s a good way to dispose of stock without sending it to a landfill site or paying for disposal.

Most inventory management software gives bundling options. By using these options, you can create a unique bundle product number, or SKU, and link the separate items to the ‘parent’ or bundle product number. This removes the separate items out of stock and sells the bundled product as one unit. If your wholesale software does not offer this feature, do it by creating a bundle product. To do so, remove the individual products from the inventory system, and link them to the bundle product using a reference field. Transparency is important for auditing and stock count purposes.

- Remarketing. Another option is to remarket your slow-moving items to a different market sector, even if it means reducing prices and creating a new marketing campaign.

- Donating. Inquire whether you qualify for a tax rebate if you donate stock to charity.

Donating, remarketing, or bundling stock is better than sending it to landfill sites and is eco-friendly, too. However, if all else fails, there are companies that will dispose of your dead stock when necessary.

- Giving stocks back to the manufacturer. Also, note that some manufacturers may be prepared to take the redundant stock back at reduced prices or give you credit.

9. Supply chain awareness.

Local and global conditions impact supply chains. They can drive prices up, cause stock surpluses or shortages, and affect delivery schedules. Inventory managers need effective supply chain visibility and an overview of market conditions. This helps them react timeously to any threats that may pose a risk to their business.

Calculate your average order fulfillment cost per order, taking into account:

- Storage costs.

- Receiving, picking, and packing labor costs.

- Administration, labels, and shipping costs.

- Return management.

10. Optimize your logistics processes.

An organized logistics network is essential for efficient and rapid management of stock acquisitions and customer deliveries. This will help maintain a smooth warehouse workflow and contribute to sustainable inventory levels.

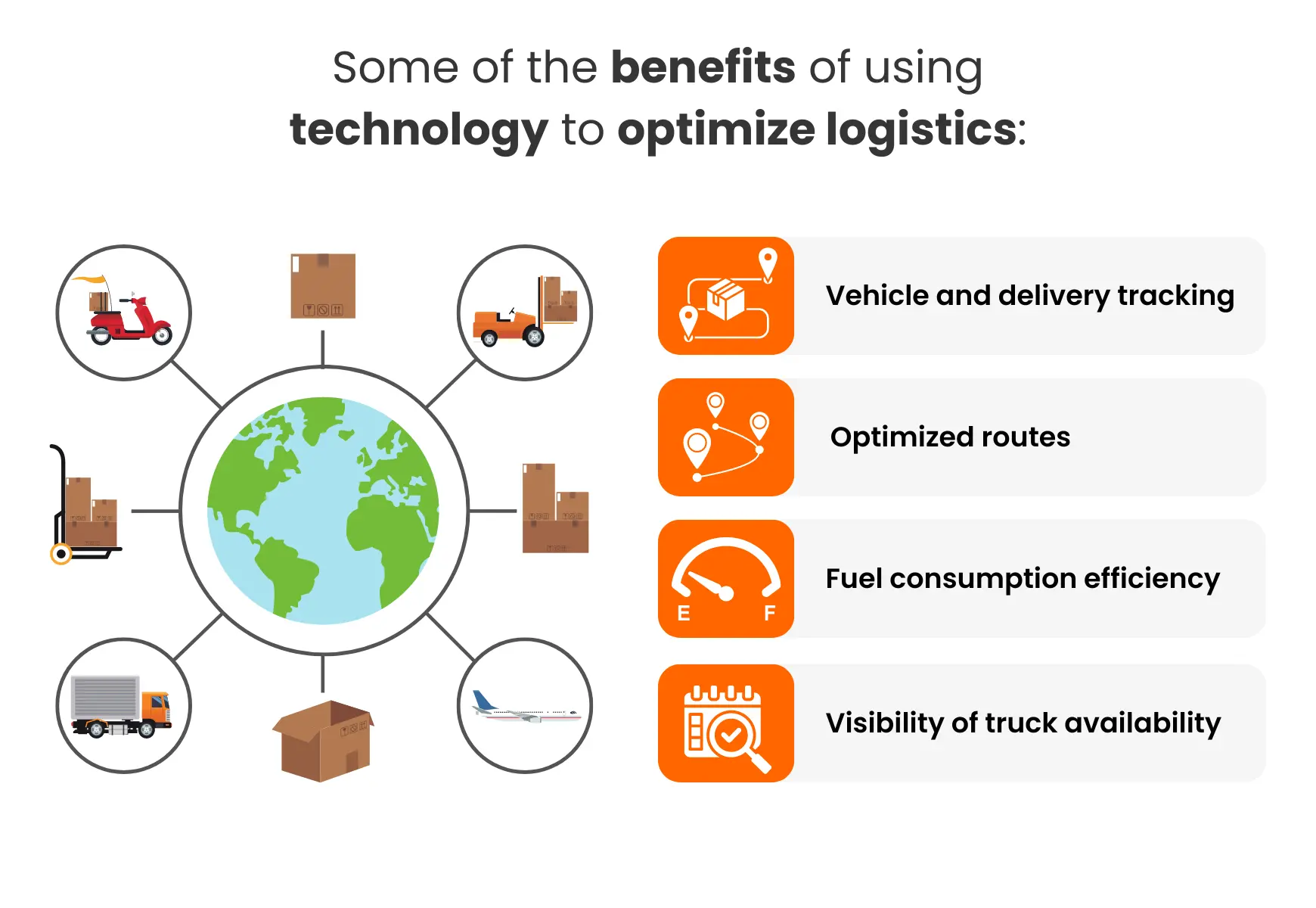

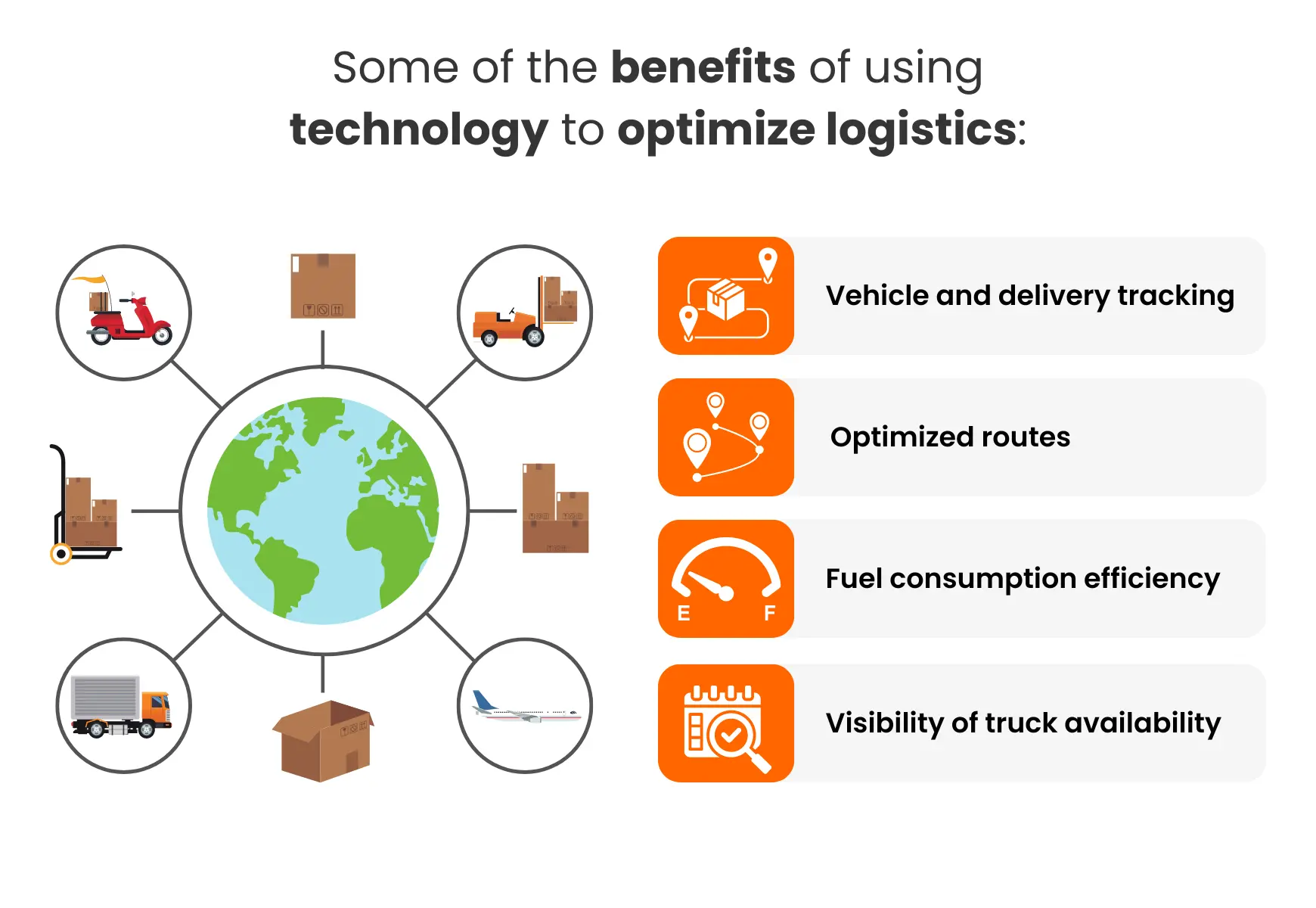

Use of technology

Technology can play an important role in the area of logistics:

- Vehicle and delivery tracking. Digital technology improves the visibility of the delivery and collection processes.

- Efficient routes. Route planning software promotes efficient route planning and speeds up deliveries.

- The latest logistics systems provide vehicle tracking functionality and route planning features. Those features optimize delivery times and ensure a transparent delivery experience for customers and dispatchers.

One of the most problematic sections within the supply chain is the last-mile delivery process. During this last leg of the product’s journey:

- Trucks can break down.

- Errors made during packing result in incorrect stock items or quantities.

- Incorrect delivery addresses are supplied.

- Vehicles run into traffic snags or bad weather.

Installing suitable software to mitigate these factors improves delivery times and communications. This results in fuel savings and reduced risks of stock in transit and facilitates exceptional customer service.

Vehicle maintenance and monitoring

Vehicles need routine maintenance if they are to function optimally. Breakdowns can be expensive in terms of both repairs and wasted time. Sophisticated vehicle tracking devices can be installed in vehicles that:

- Track truck locations.

- Monitor vehicle performance and fuel consumption.

- Monitors driver behavior and rest stops.

Providing your drivers with the tool to communicate with customers and dispatch personnel will help you improve customer relations. Moreover, this can help to mitigate risks posed by bad weather and traffic situations.

Tracking devices can be used in the following ways:

- Uploaded into a warehouse management system (WMS) or enterprise resources planning (ERP) system for planning and reporting purposes.

- Monitoring driver hours and rest stops as driver fatigue is a common cause of delivery truck accidents.

Effective route planning

- Shortest, quickest route. This saves time and fuel. Effective route planners ensure that deliveries are planned by area and time slots. This helps to avoid repeat stops and backtracking along the same routes.

- Fuel efficiency. Choosing a route that does not involve steep gradients or bad roads is sometimes preferable to doing the shortest route. Check this cost-per-mile calculator.

- Truck availability. Heavy or bulky cargo is often restricted to larger trucks. Cargo allocation to vehicles is based on size and packing capacity. Route planning will help you reduce your fleet over time or, alternatively, expand your business with the extra vehicle capacity at your disposal.

Last-mile delivery software ensures efficient communications between customers, drivers, and dispatchers. The latest technology in mobile apps enables customers to track their packages in real-time and even accept deliveries remotely. A mobile app on the driver’s phone photographs the package's delivery, which is immediately uploaded into your B2B inventory management system as Proof of Delivery.

Embrace technology for wholesale success.

Digital technology is here to stay, and the sooner you adopt it in your business, the sooner you can control processes that currently cause bottlenecks in your workflow and cost money. Wholesale distribution industry trends are various; check those here.

Successful businesses today run sophisticated systems that help them monitor their current processes and costs, forecast future business scenarios, and plan future strategies. This is the future of wholesale warehousing.

If you need to optimize deliveries for your wholesale business by optimizing delivery routes, providing real-time tracking, in-depth data analytics, streamlining order management, and more, try Track-POD.

- wholesale inventory management

About The Author

Jennifer Collins

A seasoned content writer with a passion for unraveling the intricate world of logistics through words.