Logistics Route Planning and Optimization: Most Important Aspects

Logistics route planning and optimization are used interchangeably; they have significant differences that make them unique.

Read More

If you're immersed in the world of logistics, you understand the pivotal role of automated delivery route scheduling. Leveraging route optimization software is not just a choice; it's a necessity for any logistics manager aiming to maximize their resources efficiently. No one wants to spend hours manually scheduling logistics while leaving room for potential human errors.

In this article, we will explore 5 advanced tips to elevate your automated scheduling game and achieve optimal results in your logistics operations.

5 tips to optimize automated delivery route scheduling

2. Test optimization strategies

5. Tap into predictive analytics

Commercial vehicles come in various shapes and sizes—trucks, cars, motorcycles, cargo bikes, and more. Each has distinct capacities and restrictions, requiring tailored routing and scheduling strategies.

The good news is that you don't have to handle this complexity manually.

By using advanced logistics solutions like Track-POD, you can streamline the process by specifying the type of vehicle for route creation.

The software, for instance, supports three vehicle types:

Your routes will dynamically adjust based on the chosen vehicle type, considering the unique characteristics and restrictions associated with each. This level of automation ensures efficient and accurate route scheduling.

Route optimization algorithms vary, and even within a single algorithm, multiple strategies and options exist.

Taking the time to explore these different strategies is a worthwhile investment with long-term payoffs.

Platforms like Track-POD offer diverse route optimization strategies:

Testing these strategies based on the specific needs of your fleet, whether gas trucks, electric vehicles, or bikes, allows you to choose the one that aligns best with your objectives.

Efficient route scheduling extends beyond the initial plan. For recurring routes or scenarios where some orders don't fit within specified time windows, such as milk runs, automation is key.

Utilizing features like recurring routes and quick duplication from your routing dashboard, as offered by Track-POD, is essential for scheduling logistics regular deliveries or collections.

Moreover, in cases where orders cannot be accommodated within the designated time slots, especially for multi-day routes, Track-POD provides a valuable feature. This feature allows you to instruct the system to reschedule deliveries or collections to the next day, respecting customers' preferred time slots.

This automation not only saves time but also ensures adherence to customer preferences.

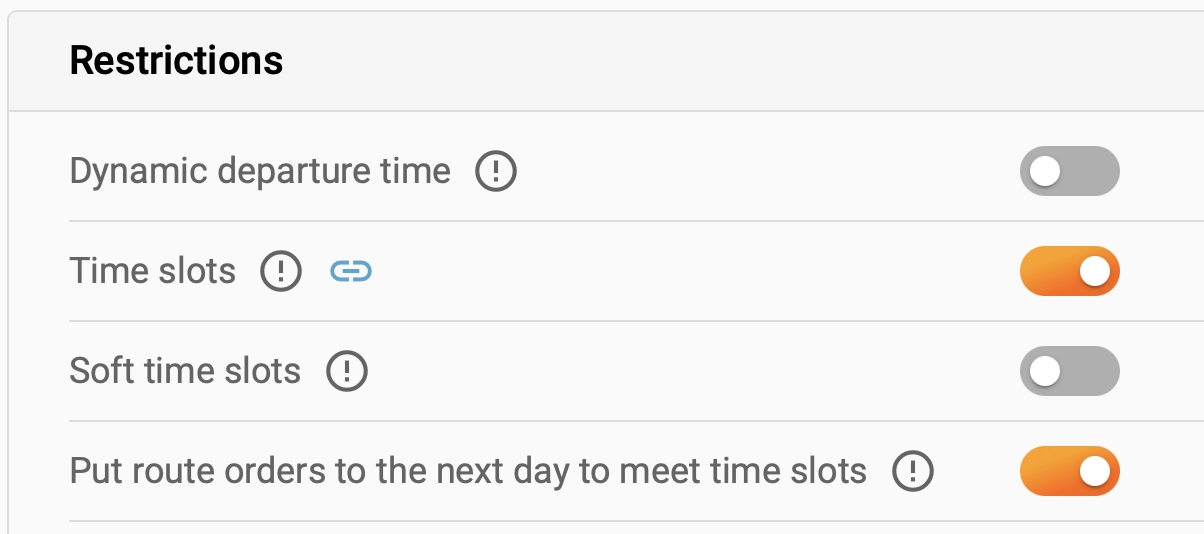

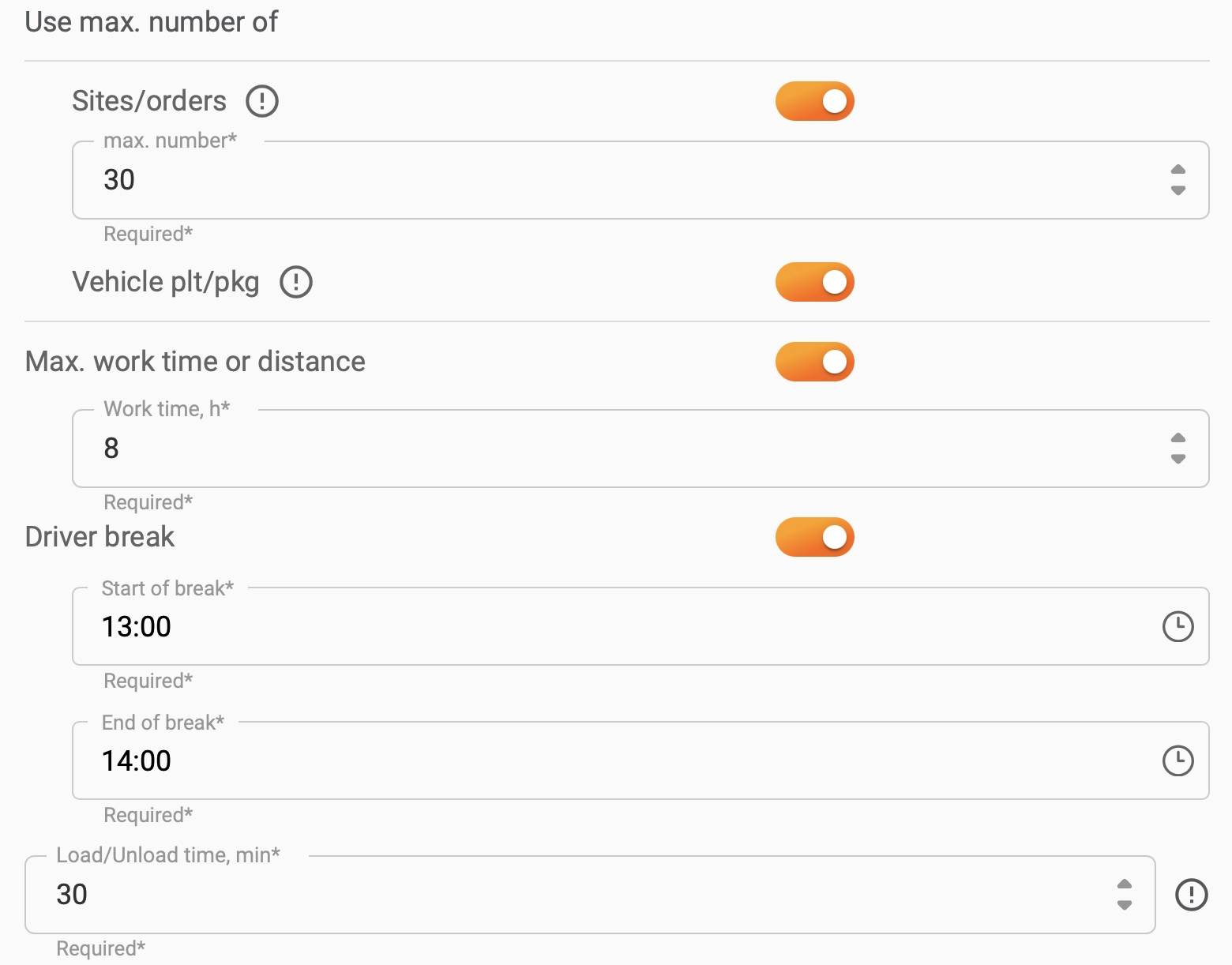

In the realm of advanced, automated routing and scheduling for commercial vehicle fleets, understanding and inputting your restrictions are crucial. Beyond vehicle capacity, factors such as work shifts, breaks, travel time, and service time play pivotal roles, especially for fleets involved in field service.

Platforms like Track-POD enable you to specify various restrictions, such as the maximum number of sites/orders planned in one route within a specific timeframe. Considering these human and operational factors ensures that the system generates realistic and achievable routes.

Moving beyond standard routing and scheduling strategies, predictive analytics emerges as a powerful tool.

Instead of relying solely on experience-based adjustments to settings, predictive analytics allows you to make data-informed decisions.

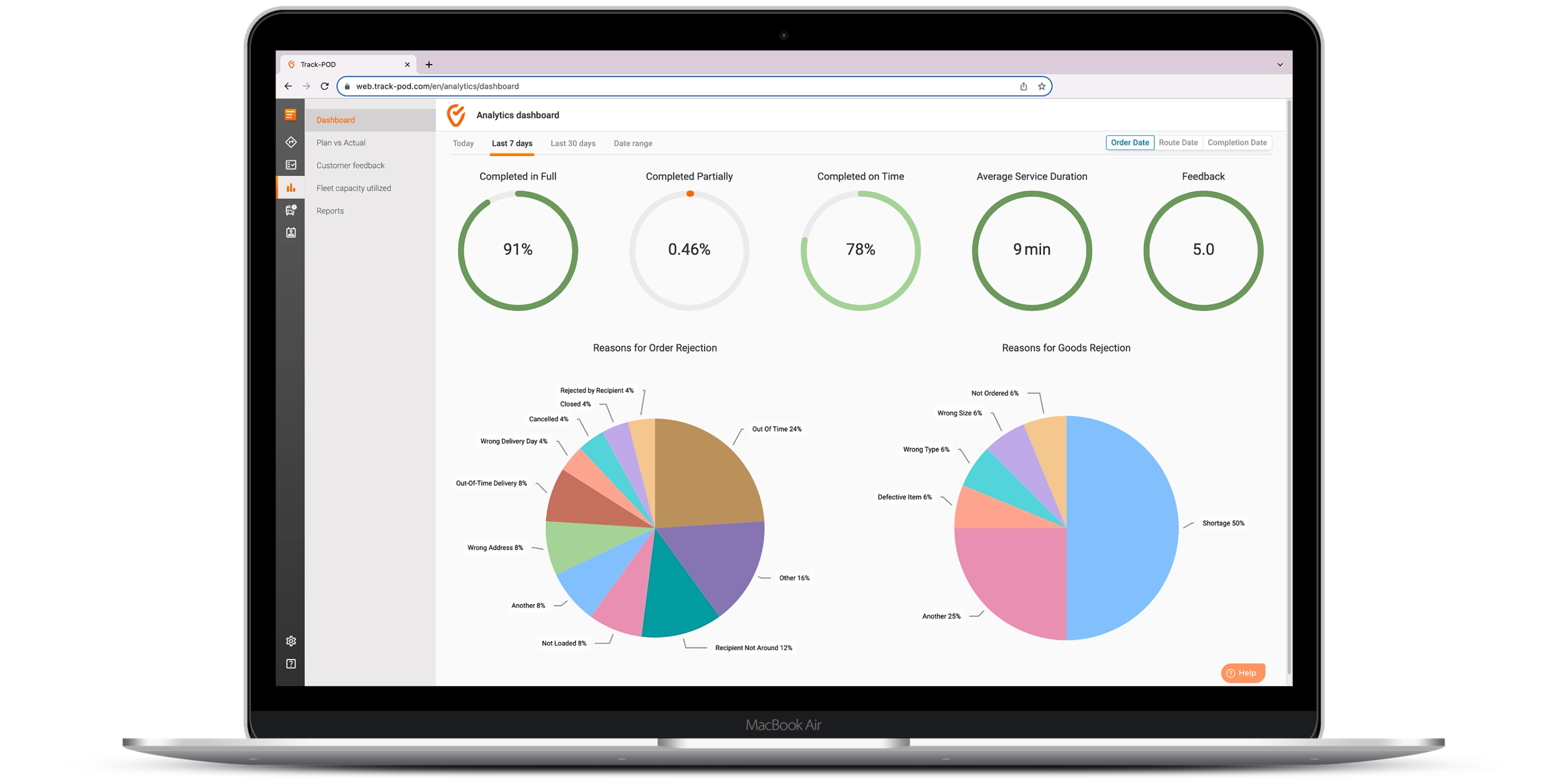

Track-POD offers a suite of analytics tools, both real-time and historical, such as shipping reports, providing insights into planned vs. actual performance.

By leveraging these analytics, businesses can make informed, cost-effective decisions and continuously improve their last-mile delivery strategies.

While several route planners excel in route scheduling and deliveries, achieving maximum efficiency and top-notch customer service requires scheduling software with full automation and advanced features.

Track-POD's routing software addresses the challenges of last-mile delivery, helping fleet managers save time and optimize costs.

If you're intrigued by the advanced route planning features discussed in this article, kickstart your journey by starting a free trial today. Reduce your planning time and elevate your logistics operations right away.

Are you currently in the process of routing and scheduling a new delivery route? The automated features discussed here can significantly streamline your logistics operations, saving time and enhancing overall efficiency.